Future Aerospace Oven

Focusing on flight attendants and airplane efficiency

Student project

Group members: N.Rinkes, R.Hoek, X.Zhang, Q.Wang

TUDelft

2024/25 - 20 Weeks

The problem

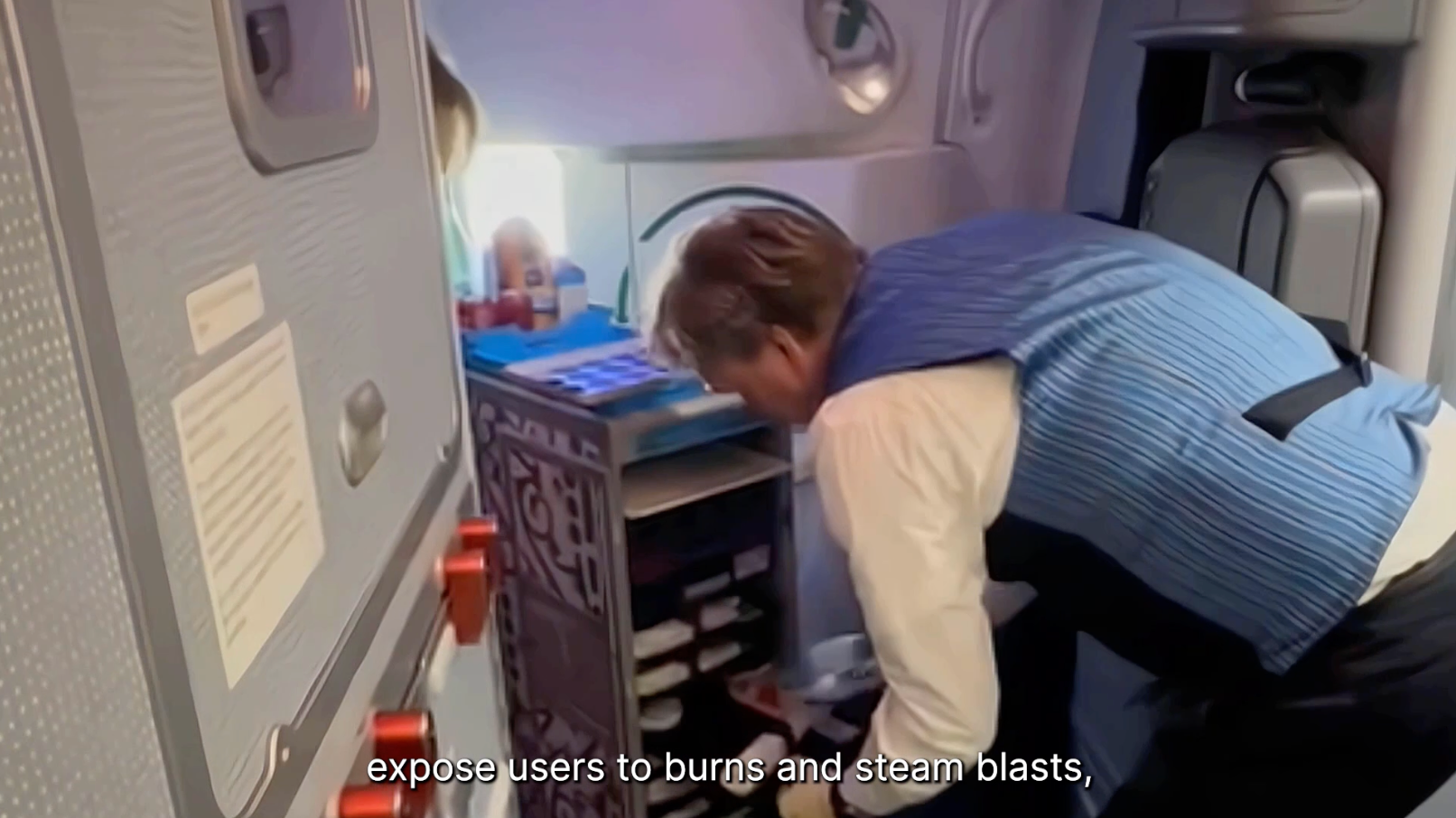

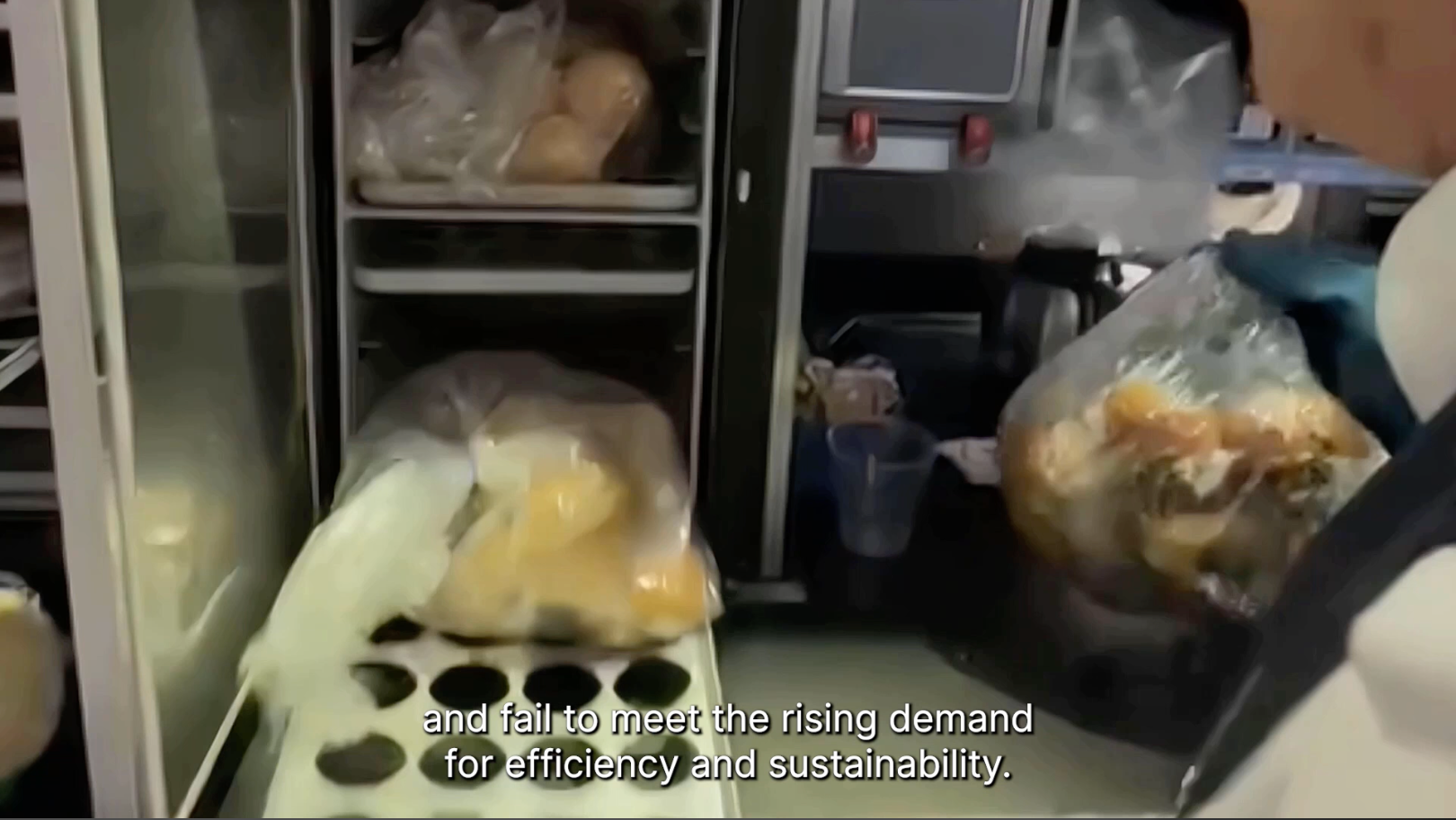

Plane guests love warm meals and airlines have to provide them. Large aircrafts are equipped with up to 36 identical ovens. Flight attendants are stressed to start each oven and are frequently exposed to hot steam exploding in their face or their arms burning on the side of the door. These ovens are part of an throughly engineered ecosystem which is required to withstand great forces and meet aerospace regulations.

Concept to be realised within 5 years

To address the future of an aerospace oven we wanted to improve the usability of the ovens and also the energy and weight efficiency. This concept should be plausible to be launched with the next generation aircraft in five years.

The future galley in aircrafts

When flying becomes increasingly comfortable and tailored towards customers the centre of it will be an array of ovens providing freshly heated meals. These ovens will be designed to assist flight attendants being safe, efficient and easy to use.

The process

Through interviews with over 20 international flight attendants (Dutch, German and Chinese). Qualitative and Quantitative findings were statistically documented and lead to meaningful design decisions.

Interviews with KLM flight attendants

Video documentation sent to us by KLM flight attendants.

Interview insights led to assumptions, that led to prototyping and validation

Sliding door challenges

Requires space inside the oven

Controllable sliding motion

Folding door challenges

Requires space above the oven

Air tight hinge & longevity

Handle height when opened

The final design

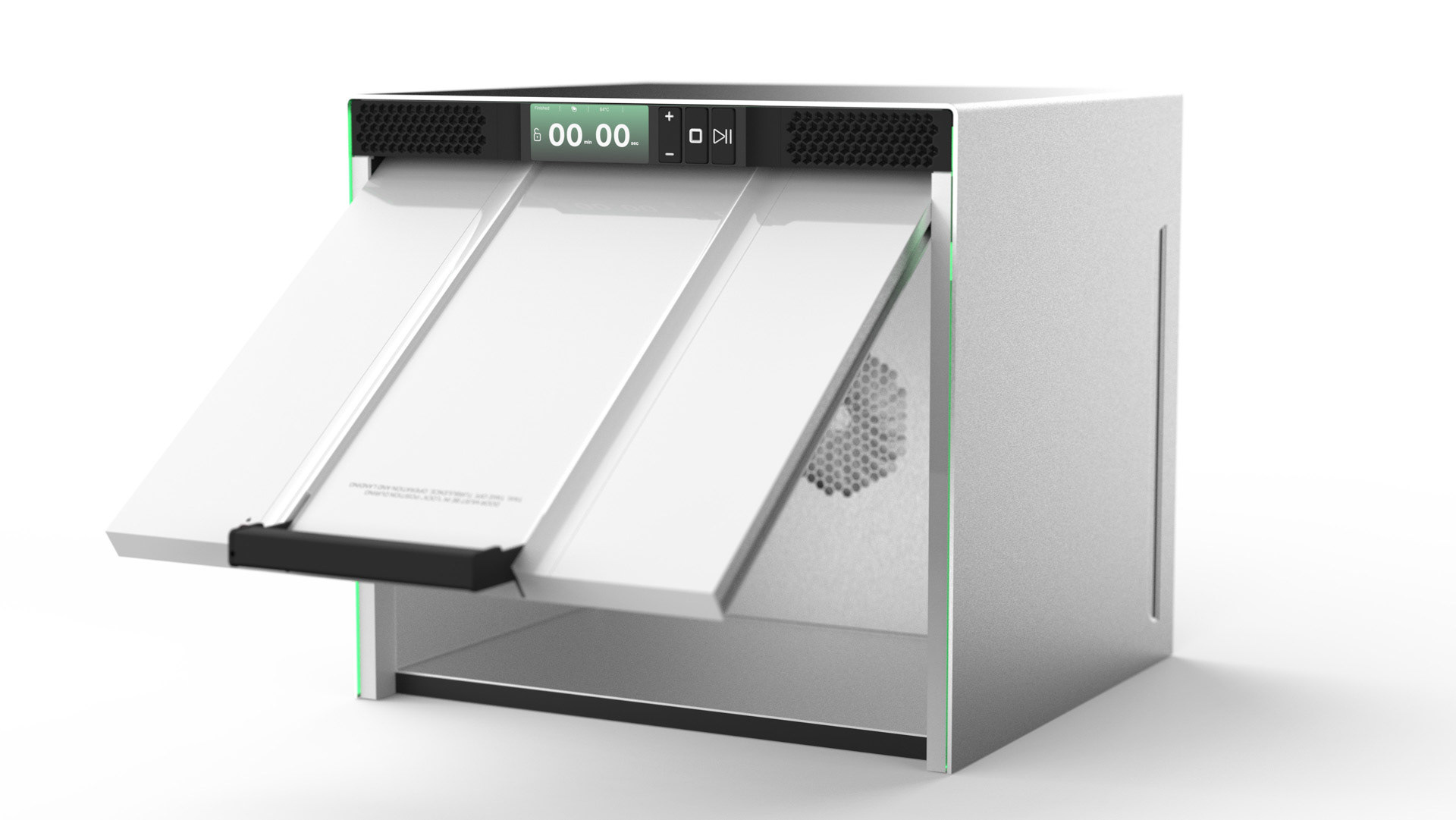

More sustainable, safer, faster and efficient

Double width

By changing the ovens outer dimensions to exactly double this results in minimal galley changes and weight savings. Each double sized oven saves around 4.8kg compared to two small ovens.

Door motion

Opening upwards prevents the hot surface to be exposed or the door from being mis used as a tray. Fully stowed the handle stays exposed allowing fast closing. When opening the door fully retracts in one motion and requires little effort due to springs.

Always front facing handle

Hot surfaces disappear into the oven

Minimising space in the galley

The mechanism behind the motion

Rails, spring loaded hinges, tension cables and rotation axles allowed us to make a prototype of the door.

This mechanism is inspired by the NEFF Slide & Hide oven. We have changed dimensions and reduced weight to optimise for aerospace use.

Safety

Hot steam and water droplets eject when the ovens when opened quickly.

2-step unlock allows for secure door movement to de-steam before opening

Locking mechanism

The locking is robust, allows motorised opening (de-steaming) and being slammed shut.

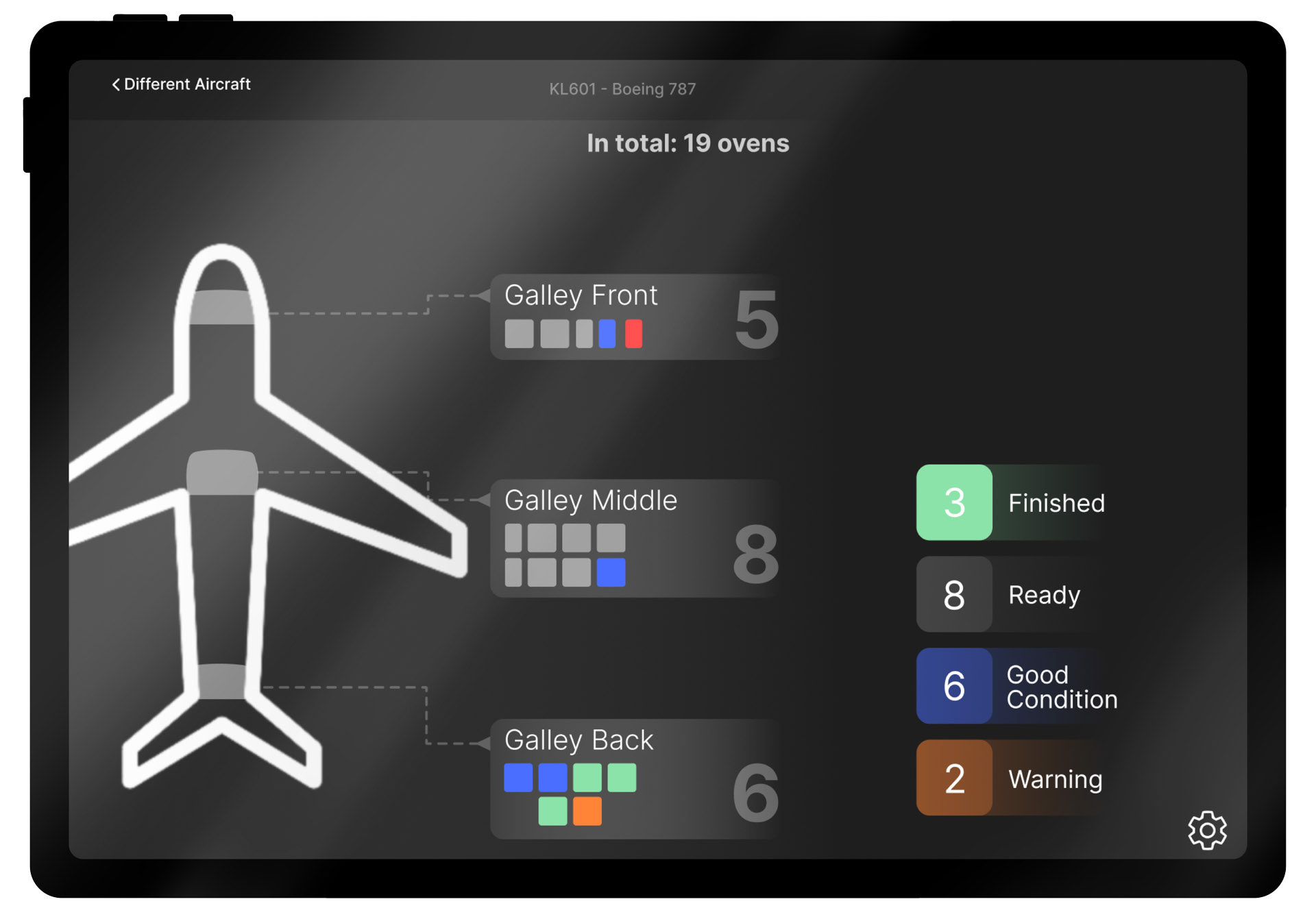

Centralised control

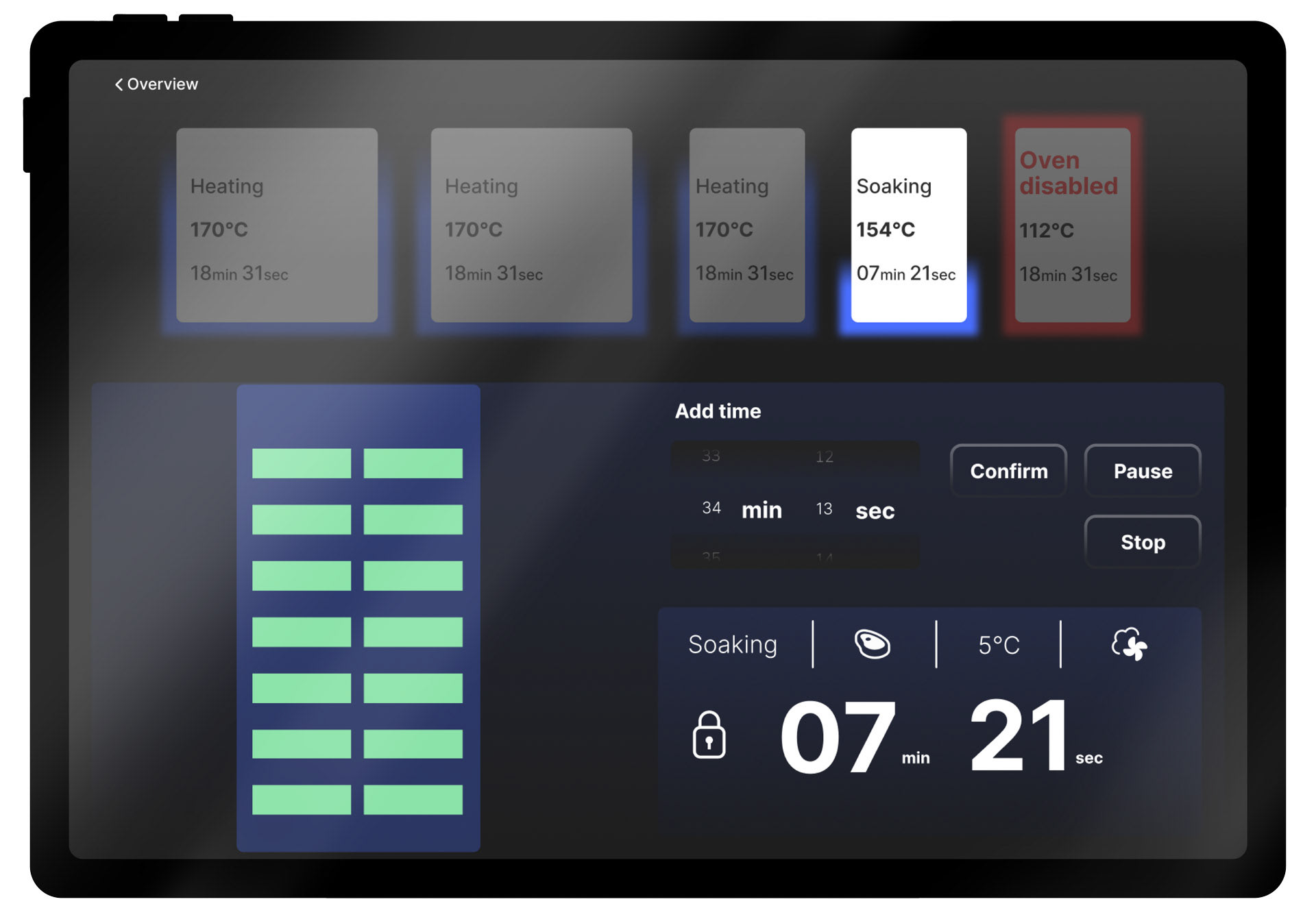

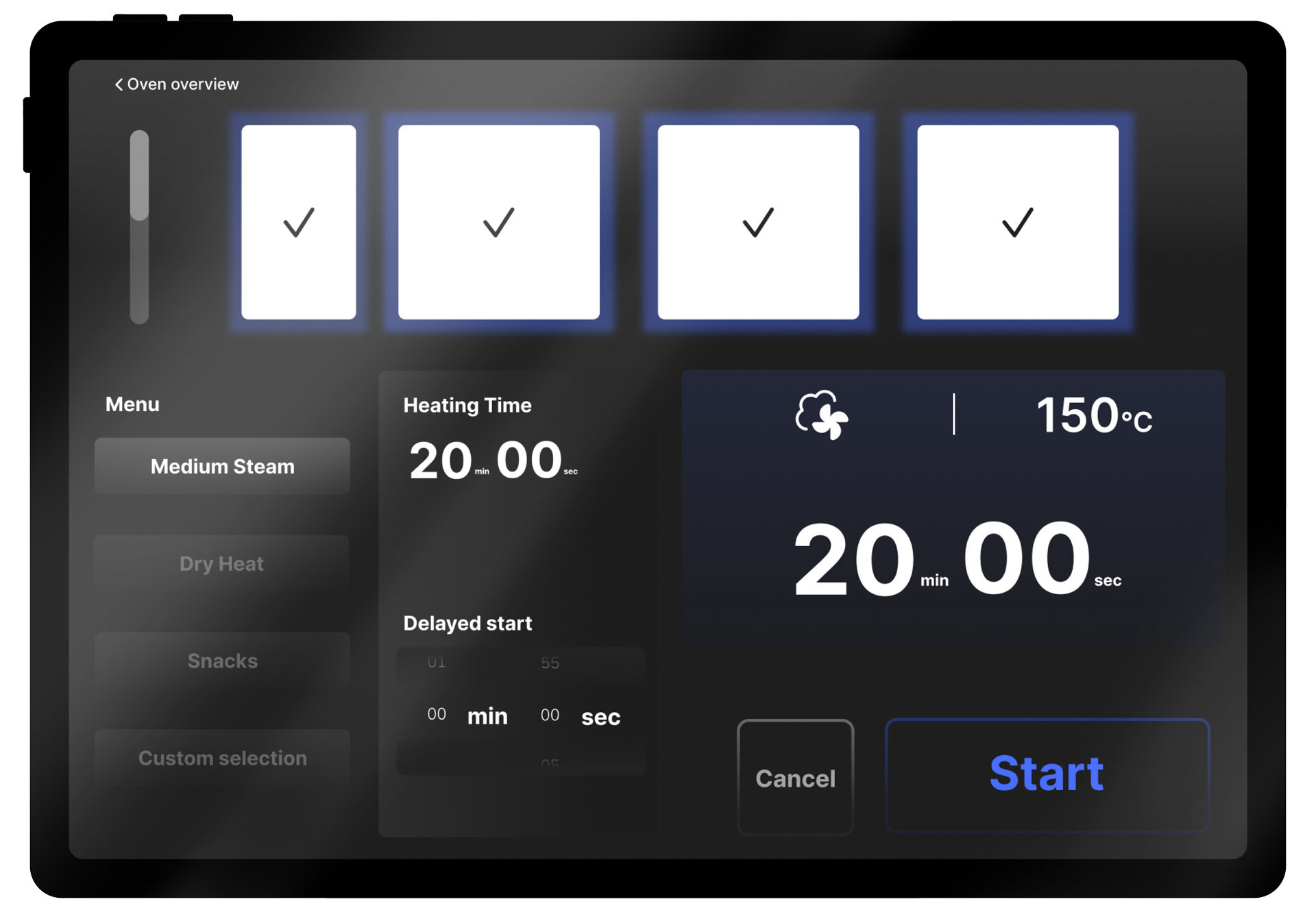

To capitalise on existing tablets aboard each aircraft we've developed an interface which allows controlling individual, grouped or all ovens at once. Reducing stress and increasing speed, oversight and efficiency for flight attendants.

Aircraft overview

Oven information

Grouped oven setup

On-oven controls

Local controls on the ovens allow spontaneous changes and functional security.

Prototype

We built a 1:1 final prototype which showcased the LED strip functionalities, double width, on-oven interface, and sliding door. The handle levelled and was squeezable, which unlocked a latch and kept the springs lifting the door.